Kurita Internship Program for Kurita scholarship awardees was conducted from 24th June to 30th June in Japan.

Mr. Nandana Hewawasamge Sajith Madhawa Premarathna, Masters student from the Environmental Engineering and Management Program, Department of Energy, Environment and Climate Change took part in the internship program. The interns have visited three Kurita facilities namely;

- Kurita Global Technology Center

Kurita Global Technology Center, focuses on the development of new technologies for water related industrial processes and production of chemicals to improve water quality to be effectively used in industrial processes which consume large volumes of water. Some industrial processes which use these services include boiler water treatment, cooling water treatment, wastewater recovery, ultrapure water production, etc.

The interns toured the facility after a brief introduction. “It was a great opportunity for me to gain some insight on the current trends and requirements for industrial water supply. The development processes such as waste water recovery are very important for the protection of natural water resources because, the current natural water resources suitable for consumption are decreasing each day. Therefore, it is a timely need to manage the remaining consumable water in a sustainable manner, while continuing the production processes without disturbing the supply chain or value chain, in order to fulfill the human demand. These new technologies and chemicals to improve the industrial process will come in handy in achieving those goals.” Mr. Nandana Hewawasamge Sajith Madhawa Premarathna.

- Kurita Analysis Services Co.

The interns visited Kurita Analysis Services Co. on 26th June, where Mr. Taya San, the Director of the facility presented the details of the services. The facility analyzes more than a thousand of water samples every day for 10 water quality parameters such as pH, alkalinity, acidity, etc. “It was a great practical experience witnessing the operation of the state-of-the-art equipments modified for specific purposes. One such modification was made to a blood sample analysis equipment to measure water quality parameters.” Mr. Nandana.

Another unit of the facility does the quality check for pharmaceutical products. The facility provides quality testing service to the small pharmaceutical businesses. This newly added service has generated good revenue as per the Director.

- Kurita Hakusan Plant

On June 27, the interns visited JDI Hakusan Plant where Mr. Kosei san explained and demonstrated the ultra-pure water production and wastewater treatment and recovery.

The interns learned about the advanced equipments such as Double Bed Polisher,

High Speed Dissolved Air Flotation and Calcium High Density Sludge System. “The knowledge I obtained from this visit will be very useful for me to apply in my country to improve the existing treatment systems.” Mr. Nandana.

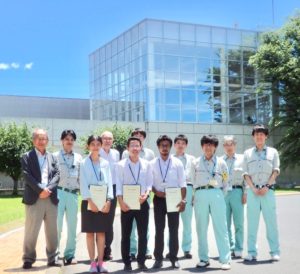

The interns gathered at Global Technology Center on the 28 June for a series of presentations and discussions on the research and studies conducted by Kurita. The interns also shared their experience and lessons from the visit.

The interns presented their thesis proposals on 29 June 2018. They were thankful to the Kurita for the wonderful opportunity to learn about Kurita facilities and research activities.

This article is contributed by Mr. Nandana Hewawasamge Sajith Madhawa Premarathna, Masters student from the Environmental Engineering and Management Program, Department of Energy, Environment and Climate Change.